What Is Field Welding? – In Depth Answers

This post contains affiliate links.

While shop welding makes up a large part of the fabrication process, field welding requires a different set of skills and equipment.

Shop welding is convenient because fabricators can build railings, staircases, and ornamental pieces on long, flat welding tables. All of their tools are conveniently at their disposal, and it is much easier to get every dimension perfect. Welding in this controlled environment improves the quality of many different projects.

Although shop welding is convenient, a lot of the final products must be installed at the job site. Projects like handrails, spiral staircases and beams must be transported to the job site and welded in properly. This is where welding “in the field” comes into play.

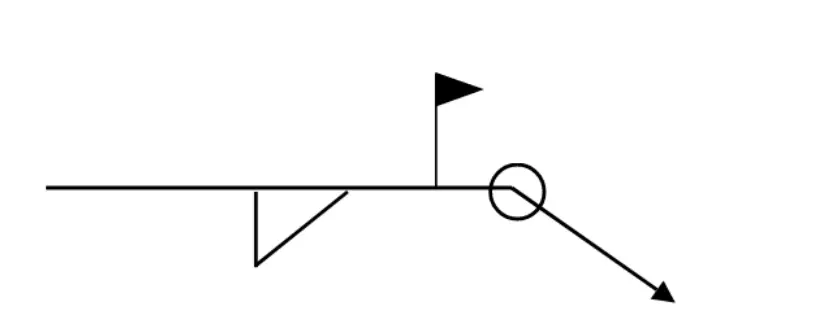

The field weld symbol is characterized by a small flag on top of the reference line. This means that the shop guys won’t be performing welds on the piece once it is finished, and the field welders will now take over.

Ornamental Field Welds

Often times field welds are very simple and don’t take much time. Installing a valence could be as easy as a few quick TIG welds. Installing handrails and staircases takes a bit more time; with bolts, wedge anchors and epoxy often making up a larger part of the installation process.

However, some field welds can be very complicated. Welding inside of a finished, high end house can be nerve racking. Welders have to take preventive measures to make sure that nothing is damaged during the field welding process. This often means protecting high end windows and woodwork before the field welding process begins.

Protective coverings like Ram Board are often used in field welding procedures. Protecting finished work is often more time consuming than the actual welding process itself. Construction job contractors can end up spending thousands of dollars just on protective sheathing/boards.

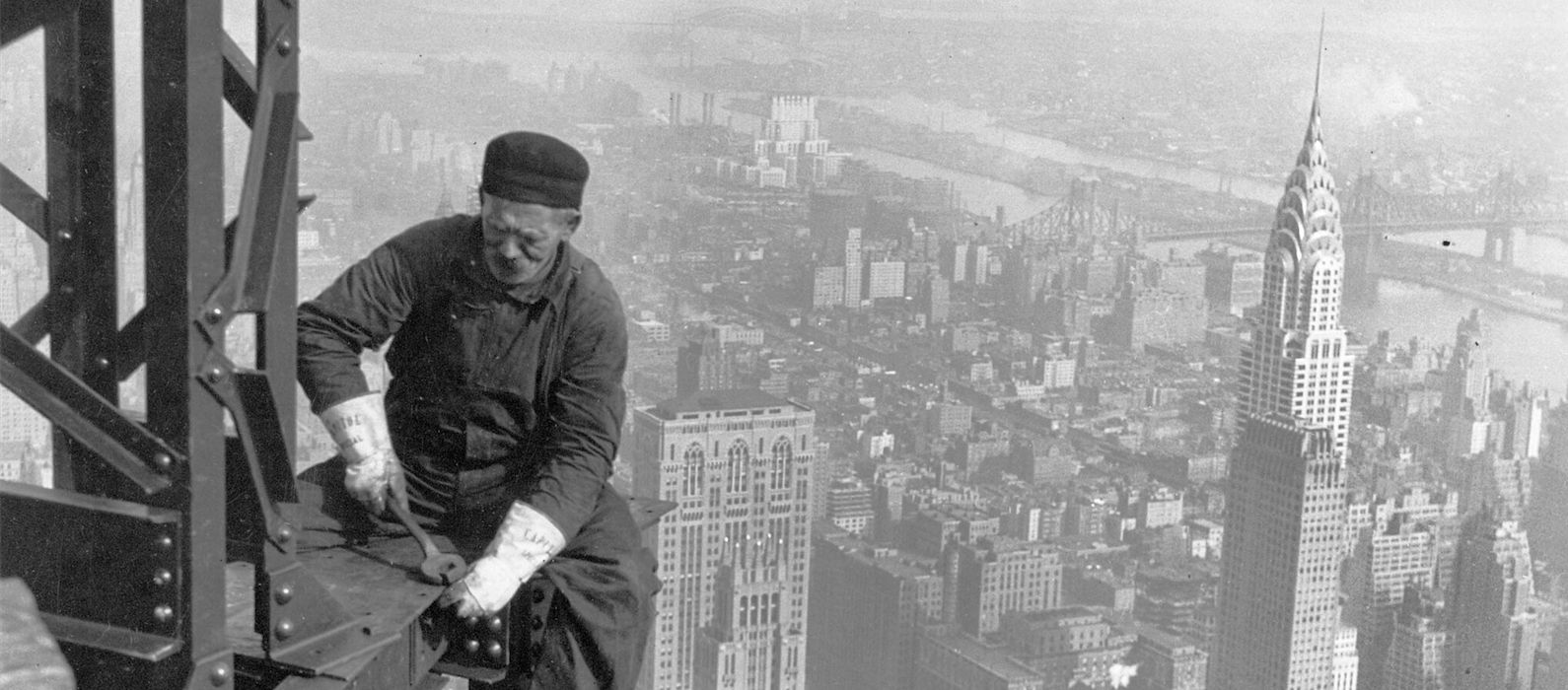

Structural Field Welds

For beams that are fabricated in a shop, common procedure is to either bolt them in at the job site or weld them in. Ironworking has very specific protocols and engineers are the ultimate judge of how the beams are installed. Blueprints must be followed very closely, and mistakes aren’t tolerated on these structural projects.

Structural field welding often involves using the stick process due to its convenience factor. The engine drive machine can be 4 stories below the welder, and long enough leads can reach up to where the welding is taking place. The stinger must obviously be in the hand of the welder, but the ground clamp can be a few hundred feet away from where the welding is taking place. However, all of the beams are interconnected – so this is not a problem.

Dual shield flux core MIG has gotten more popular with structural field welding, but it is more of a pain to deal with a MIG machine on the job site. Long extension cords and long MIG cables are needed, as well as larger gas cylinders that can be tough to move. Because of this hassle, many welders prefer to stay with the stick welding process.

The Field vs The Shop

Larger welding companies will have multiple crews that perform different operations. The shop workers are either building ornamental pieces – or fabricating beams and larger structural items.

The field guys/girls are either installing the ornamental work at the job site, or installing structural items on larger job sites. Welders that strictly install beams and heavier steel are referred to as ironworkers. “Hanging iron” is a grueling process, and these workers are often paid more than the shop welders.

Mobile welding is almost all field work. Repairs and pipeline welding are strictly referred to as “Field Work”.

Wrap Up

Whether you prefer to fabricate in the shop or weld in the field, it is good to be well rounded with both categories. If you’re proficient with both, you’ll be more valuable to your employer, and will progress faster in your companies rankings.

If you can fabricate and weld in the field, it will also make it easier to start your own side hustle. This may even turn into a full time personal business at some point.

Featured image credit : Flickr (via Ping news photo service)