Is Welding School Worth It?

This post contains affiliate links.

There is no doubt that welding is a great trade. It is a rewarding career that is a solid option for folks who want to learn a trade.

Like any trade or blue collar profession, there is a specific skill set that is needed to break into the business. Welding is no exception. There are many ways to learn how to weld, but one of the more traditional ways is to go to welding school (usually a 2 year program).

The other common ways to learn welding are: an apprenticeship, teaching yourself, being a “welder helper” on the pipeline, etc.

These can all work, but they may not offer the most in depth approach. Good welding schools are well rounded, and will teach beginners all processes before they head out into the work force.

Welding School

One thing that turns people away from trade school is the commitment. There is a lot of time and money involved in a 2 year trade program, and it does take persistence and dedication.

Though trade schools are often cheaper than regular colleges, it is still a large sum of cash that some people aren’t willing to pay. Plenty of people aren’t able to pay these tuition costs, and taking out students loans can be daunting – we know!

For people who have the willingness to commit to welding school, it is a rewarding experience that will set you up for a promising career. However, you must be sure to get the most out of your classes. If you’re not willing to stay after school sometimes and work on your beads – you won’t progress nearly as much.

Retaining the most out of your classes will take discipline, but you will be opened up to a world of jobs when you graduate.

Keep in mind that every welding school varies greatly from the next one. This article will cover some common classes that we went through at school, and how they helped us to get where we’re at.

Intro Classes

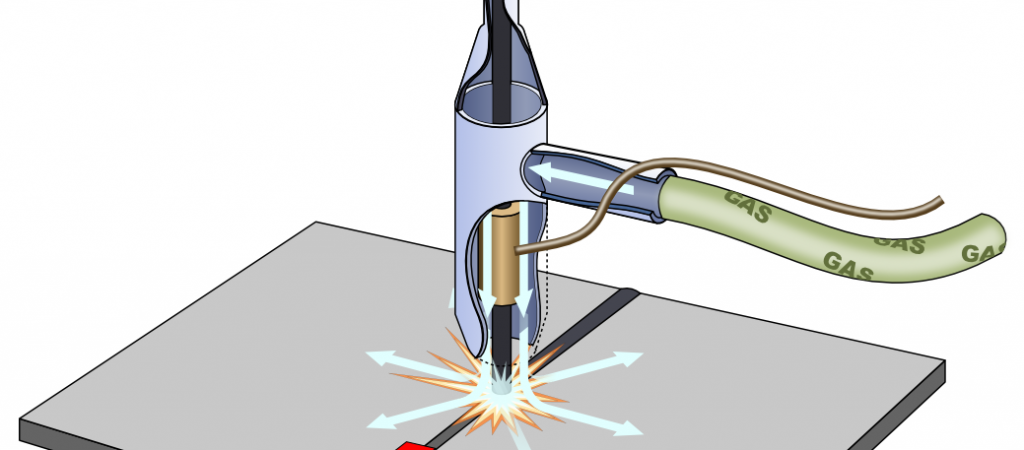

For schools with a more traditional approach, the first classes won’t involve welding at all. Starting out with a cutting course is quite common. In these classes, students learn how to cut steel with oxy-acetylene and oxy-propylene torches.

Since every welding job requires torch cutting, having this skill is a no brainer. Learning how to run a cutting torch is essential and it will serve you well throughout your career.

Schools may also teach students how to use a plasma cutter. These more modern torches are another quick way of cutting steel – and most welding shops have a plasma cutter that is used on a regular basis.

Another popular intro class is an oxy-acetylene welding class. This is a primitive version of welding and it is similar to TIG. Your torch makes a puddle and you feed filler rod with your non dominant hand. Though this method is becoming dated, it is still part of welding history and it is a good skill to have.

Blueprint Classes

Reading blueprints is necessary for fabrication and construction in general. Learning welding symbols and layout will help students when they land their first job.

Welding has its own set of symbols specific to the trade. Memorizing and knowing these symbols is mandatory if you want to call yourself a welder.

Although blueprint classes can be boring at times, you’ll probably be glad you took the course. When your future boss hands you a blueprint and says “build this” you will have a better idea of how to get started.

If you have no blueprint knowledge, the first weeks of your new job could be quite rough.

Stick Welding Classes

Arc welding (stick welding) is one of the most popular methods. Running 7018 and 6010 beads is an awesome skill to have.

Our school taught several stick classes that prepared students for an AWS (American Welding Society) plate test at the end. Passing the plate test in a 3G (vertical) or 4G (overhead) position will give you the certification for structural stick welding.

It usually takes at least a full semester to prepare for one of these tests.

MIG Welding Classes

MIG classes are a must for any welding school. Learning hardwire (regular) MIG will allow students to get introduced to one of the most popular processes.

Many schools also show students how to run stainless MIG wire. This is a less common process with its own skill set. Stainless MIG has a more sluggish bead and is harder to manipulate. If you can master this, that is a good accomplishment. Stainless just feels different than regular hardwire, so it’s good to get some practice with.

Learning how to run aluminum MIG is also essential. These machines can be very temperamental and will cause beginners to get frustrated. Once you can do aluminum MIG, your resume just improved!

Dual shield flux core is typically what students will use to take their plate test. This structural wire is very common with ironworking and larger projects. Once this course is completed, students will have the choice between a 3G vertical test or a 4G overhead test. Once completed, they will have earned their dual shield certification paperwork.

Good welding schools will have a CWI on staff. These certified welding inspectors will run these tests and sign off on them if the student passes the bend test.

TIG Welding Classes

Since TIG welding requires the most dexterity, these classes are usually saved for last. This isn’t a definite rule, but most schools want their students to get a feel for other processes – before they jump into TIG.

Just learning how to run a TIG bead can take some serious effort. Students will typically learn flat fillet welds before jumping into vertical and overhead joints. Gaining practice on simple joints will set students up for success.

Once they get some hood time (welding time) under their belt, students will be introduced to aluminum TIG. This is a harder process that requires even more practice than mild steel TIG. Aluminum tends to melt and do all sorts of crazy things when you add heat, so welding it isn’t an easy task.

At the end of a full semester of TIG, students will generally do another plate test. With our welding school, TIG classes did come last. I already had my stick certifications and MIG certifications. TIG was the final step.

More students fail TIG tests than other tests. It is easy to get contamination or improper penetration. If your tungsten gets contaminated, this can seriously compromise the strength of your welds. Some students may have to do a couple attempts before they receive their TIG paperwork.

Pipe Welding Classes

Though students may run some pipe joints in other classes, there is generally a separate class focused completely on pipe welding.

These classes teach a variety of pipe joints, and ultimately lead up to a 6G test. This test requires a full pipe weld when the joint is at a 45 degree angle. Due to the awkwardness of this 6G position, it encompasses flat, horizontal, vertical, and overhead at the same time.

If students can get their 6G cert, it will allow them to apply for higher paying jobs involving pipe. Since employers have trouble finding decent pipe welders, having this skill is a great asset.

Pipe students often go on to work as boilermakers or even pipeliners.

Wrap Up

If going through these courses sounds like your cup of tea, then we say go for it. Keep in mind that this list was what our school comprised of. Some welding schools differ, offering only pipe classes, only TIG classes, etc etc…

You may only want to learn one specific process, in which case you would choose a school that specialized in that process. However, if you want to land a fabrication job, learning the three main processes is probably your best bet.

It is a good choice not to limit yourself in the beginning. Getting exposure to MIG, Stick and TIG will make you much more well rounded.

It is a good idea to do lots of research before selecting a welding school. If there isn’t a decent one in your area, then relocating could be a good option. Even if you have to drive a longer commute to reach a better school – it could be worth it in the end.

The 2 year programs go by pretty fast, so it is best to select a good school instead of the nearest one. Welding school graduates have a much easier time finding jobs than some other degrees. It is a tangible skill set that will serve you for a lifetime.

Featured image credit : openclipart.org