Stick Welding Polarity – Simple Answers

This post contains affiliate links.

Different welding processes require different current types. If you select the wrong current type for your process, the results will be subpar. It is usually pretty easy to know when you’re running the wrong polarity. The welds will look awful and you’ll know something has to change. What is the right polarity for stick welding?

TIG welding on steel will require a negative polarity – in which case the torch has a negative current flowing into it, and the ground clamp has a positive flow.

Processes like stick welding require a different polarity type, which we’ll get into below.

Positive Polarity (DCEP) #1 Choice

Stick electrodes are generally run with a positive polarity (DCEP). With this setup, your electrode holder (stinger) has a positive current flowing to the stick electrode (also just called a “rod”). Your ground lead will be attached to the negative terminal of your machine.

This positive stick polarity will work with most rods when welding mild steel and even stainless steel. Once you attach your leads this way, you usually won’t have to change them.

Also, the thickness of the base metal does not affect the choice of polarity. If you are using stick welding, regardless of whether the base metal is thin or thick, DCEP is the preferred choice.

As you can see on the Bobcat above, the negative terminal is on the far left. The positive terminal is on the far right.

Some stick machines may have these switched around, but they are always labeled. Even smaller entry level machines will make it clear which terminal is which.

Some machines and manuals may refer to the negative terminal as the “work” terminal. This “work” terminology simply means that it is where your ground clamp lead should go.

So, for a majority of stick welding, Positive polarity (DCEP) is the best route. Most rods are designed with this polarity in mind, and that won’t change anytime soon. The 6010 rod, a very commonly used electrode, is used with DCEP setup.

Remember that electrode positive is also called reverse polarity in some places. So for stick welding (also called as SMAW or MMAW process by some), reverse polarity is a more suitable choice than straight polarity.

Also, some people like to convey this setting as DC positive. The term DC positive welding indicates DCEP setup.

AC Polarity (Alternating Current)

Some stick welding machines will have an AC current. This “alternating current” is constantly switching between positive polarity and negative polarity.

Older Lincoln Buzzboxes often have AC as a power supply. Some stick machines may have an AC setting in addition to their DC settings.

While most stick rods are meant to be burnt on DC polarity, some rods do well with an AC current.

Rods like 6011’s and 6013’s do great on an AC current. They run best on it and are designed with AC parameters in mind.

6013 rods offer medium penetration and are great for welding thinner steels without much warping. Running these rods is best done on an AC current. Their heat input is manageable and it tends to bend and warp metals much less than other processes.

6011 rods offer very deep penetration, and can burn through rust and even light paint. These 6011’s are the AC version of the popular 6010 rod. For root passes and heavy duty applications, 6011 electrodes are worth a try.

In SS rods, a usability designator appears at the end. For example, EXXX-15, EXXX-16, EXXX-17, EXXX-26 and so on. This designator indicates the polarity with which the rod is suitable for use.

The rods ending with 16, 17, and 26 can be used with AC current. These rods can be used with DCEP as well. However, rods ending with 15 are only suitable for use with DCEP.

So if you end up with an old AC stick machine, don’t worry – there are still some awesome rods that you can use with it!

When Is AC Polarity Preferred For Stick Welding?

In general, DCEP is the preferred polarity for stick welding. However sometimes AC polarity is resorted to, for following reasons:

- No other choice: Some older machines have a power source that puts out only AC current. Older machines of lincoln make, called buzz boxes, are an example of this type. Modern day machines of course no longer have such limitations. Although, some low cost entry level machines still give only AC output.

- Sometimes AC polarity is used as a remedy to arc blow issues. Arc blow is a phenomenon in which arc wanders from the point of arc. This happens when the base metal being welded is prone to getting magnetized, and a high diameter electrode is being used. Many remedies are available to counter this. However, switching to AC polarity is an easy to implement fix. In Coded jobs however, this would not be permitted because change of polarity is an essential variable. And therefore not permitted.

Problems Associated With AC Polarity In Stick Welding

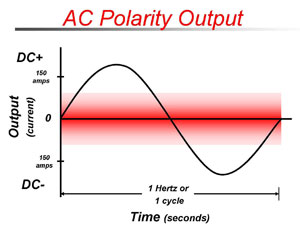

In AC welding, the current oscillates between positive and negative like a sine curve. Typically, the frequency of alternating current in most countries is 50 Hertz. So this change from negative to positive occurs 100 times per second.

This means that the current is near to zero 100 times per second. See the red zone in figure below.

This means that the arc ‘pops out’ or gets extinguished frequently during welding. To overcome this problem, rods that are specially designed to operate on AC have in their covering special ingredients that keep the arc ignited.

However, in AC welding the arc still continues to flutter. It is less stable than DC polarity.

What Polarity For E7018 electrode?

E7018 electrode is perhaps the most commonly used rod across not just the united states, but probably the world. So this question is common.

E7018 rod is designed to be suitable for use with both AC as well as DC. When using DC for 7018 rods, electrode positive polarity is used.

Negative Polarity (DCEN)

While it is uncommon, it is possible to run negative polarity (DCEN) while stick welding. It generally produces less penetration, and the rods tend to burn faster. It is worth trying out if you’re welding on very thin steel – but it isn’t the prettiest.

Stick welding with negative polarity is definitely not common practice. Many welders go their whole careers without trying it out. However, if you want to test it out then go for it – It will not damage your machine.

How To Change Polarity On A Stick Welder?

This is easy. All welding machines have two terminals marked positive and negative. The labelling appears clearly near the terminal.

If you need DCEP polarity, connect the stinger lead to the positive terminal while the ground lead goes into the negative terminal.

If you need DCEN polarity, the stinger lead goes into the negative terminal, while the ground lead goes into the positive terminal.

In modern day machines, there is a polarity switch. One can simply flip the switch to go from one polarity to another. If the switch is not available, you must interchange the welding cables as described above.

Other Aspects Of Polarity In Stick Welding

In Coded jobs, it is important that choice of polarity is frozen well in advance. ASME Section IX, which is referred by most codes of construction across united states, specifies that change of polarity is a supplementary essential variable. For stick welding, this variable appears as QW 409.4 in the Table QW 253 for shielded metal arc welding.

This means that if the welding procedure has been qualified with DCEP, the production weld must be made with DCEP as well. Likewise with DCEN too. Change of polarity from DCEP to DCEN or vice versa is not permitted.

The fact that it is a supplementary essential variable means that comes in force only when toughness is a consideration. When impact is not a consideration, then it is a non-essential variable, but still must be specified clearly on the WPS to help the welder.

For corrosion overlays and hard-facing overlays too, change in current (that is, AC or DC) and polarity (DCEP or DCEN) is an essential variable. For stick welding, this appears under QW 253.1.

An experienced welder knows the importance of polarity in welding – be it stick welding or any other kind. For a welding engineer, these variables in Section IX establish the importance of polarity.

Featured image credit: Oleksandr Panasovskyi, UA