How To Setup A Stick Welder – Machine Tips

This post contains affiliate links.

Out of all the welding machines out there, stick welding machines are one of the easiest to use. There is no external shielding gas involved, which makes them a great choice for novices who just want to get a feel for welding.

This article will cover the best way to set your stick welding machine up. Once you dial in your settings, amperage and technique – stick welding can be one of the most satisfying ways to weld.

Although the settings are pretty straightforward, stick welding technique can be very hard to master. Some people pick it up pretty fast, while others struggle with it for awhile. Since the rod is always burning and getting shorter, newbies can get frustrated with keeping consistent welds.

Although stick welding can be hard to learn, it is one of the best processes to master. You can use it for all sorts of projects – hobby welding, structural welding, pipe welding, and repair welding.

Polarity

This is one of the easiest ways to ensure a good weld. It is also one of the easiest ways to ruin a stick weld.

Most of the time, stick welding electrodes run on positive polarity (DCEP). This stands for “direct current electrode positive”. The lead cable that runs to your stinger is going to be your electrode lead. This should be attached to the positive terminal on your stick welding machine.

The lead cable that runs to your ground clamp is going to be your ground or “work lead”. This should be attached to the negative terminal on your machine.

Attachment styles vary. Some people prefer DINSE connectors while others just use a lug bolt to attach their leads to their machine. As long as the connection is solid, the current will run just fine. It is important to check your lead connections regularly, as they can corrode over time. A bad lead connection can cause your machine to malfunction, which can be dangerous.

In general, sticking to the above directions will work well. It is just the way that stick electrodes are designed. They like to be run on positive polarity to ensure the best weld possible.

Amperage

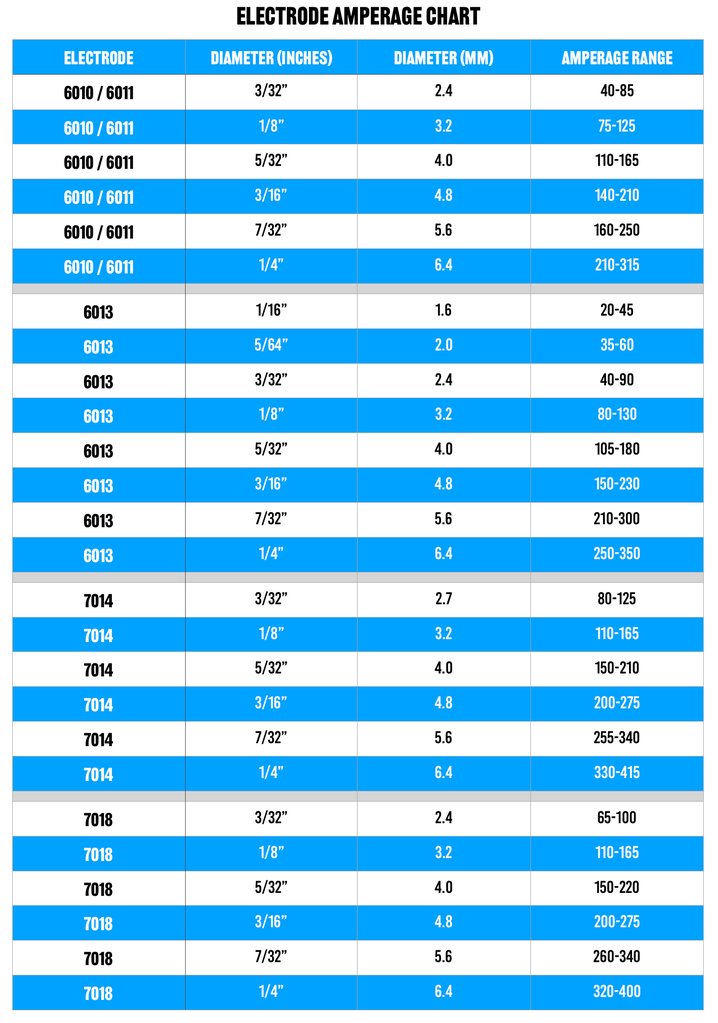

Your amperage is simply the amount of electrical current running to your stick electrode. Smaller diameter electrodes will need less amperage, while larger diameter electrodes require more amperage.

Every machine acts a bit differently, and the amperage reading is usually not 100% accurate. The chart below will give you an idea of which amperages to run.

Lower end machines will have an amperage dial, while higher end machines usually have a digital readout. The digital screens allow you to fine tune your amperage, while the dials are more vague.

Power Source

Some smaller stick welding machines will run off of 120v power outlets. These are the standard outlets found around your house or garage.

Stick welding machines capable of higher amperage will run off of 220v power outlets. These are larger outlets that typically require a 50 amp breaker. If you don’t have one of these already, you’ll likely have to get one installed.

The smaller machines can typically only burn smaller electrodes. The 120v power just doesn’t have the capability to burn 1/8″ or 5/32″ electrodes (larger sizes). So, if you have one of these smaller machines, you’ll probably be stuck with 3/32″ diameter electrodes. These rods can lay some really nice welds, but they aren’t great for big projects as they produce a smaller bead.

If you’re looking to burn larger stick electrodes, you’ll need a beefier machine that has the capability. These are usually more expensive and require much greater power consumption. Your electrical bill will be higher, but you’ll be able to burn just about any electrode you want.

A lot of newer machines will have an adapter to use either 120v power or 220v power. Depending on your needs and your power supply, you can choose which plugin to use.

A Word On Engine Drives

For mobile welders and structural welders, engine drives are a great option. Since they run off of gasoline, they have the power to burn very large electrodes.

If you’re looking to do field work or any mobile welding, it is worth looking into these machines. The Miller Bobcats and Lincoln Rangers are the most popular models, but they do get pricey. You have likely seen these machines on service trucks in your area. They allow you to pull up anywhere and begin welding.

These engine drives do require maintenance, just like a car. Oil changes and mechanical repairs will be necessary to maintain these machines.

Other Settings

Some nicer stick welding machines will have more advanced settings. These may include “Dig” and other more fancy configurations. The “Dig” refers to how deep your arc penetrates the steel. For rods like 6010’s, higher “Dig” will mean that the arc digs deeper into the steel you are welding.

Some engine drives like the Miller Pipe Pro have so many settings that it gets quite complicated. Pipeliners use these nuanced settings to get the best performance for their pipe welds.

While it is easy to get caught up in the fancy stuff, you really only need a good amperage and a proper polarity setting to get started. Even though these settings are simple, dialing in the right amperage can take some serious practice.

Featured image credit : Pixabay.com