TIG Welding Polarity – A Beginners Guide

This post contains affiliate links.

TIG welding polarity is pretty straightforward. Once you set up your machine, you shouldn’t have to change the terminal connections ever again – unless you want to stick weld.

Newer inverter machines will allow TIG polarity changes while the machine is on. These newer machines often have digital readouts that allow for quick amperage changes and TIG polarity changes. However, older transformer machines can get severely damaged if you change polarity while the machine is on. You can read more on welding machines in our guide here.

TIG Welding Polarity Options

Electrode Negative TIG (DC-)

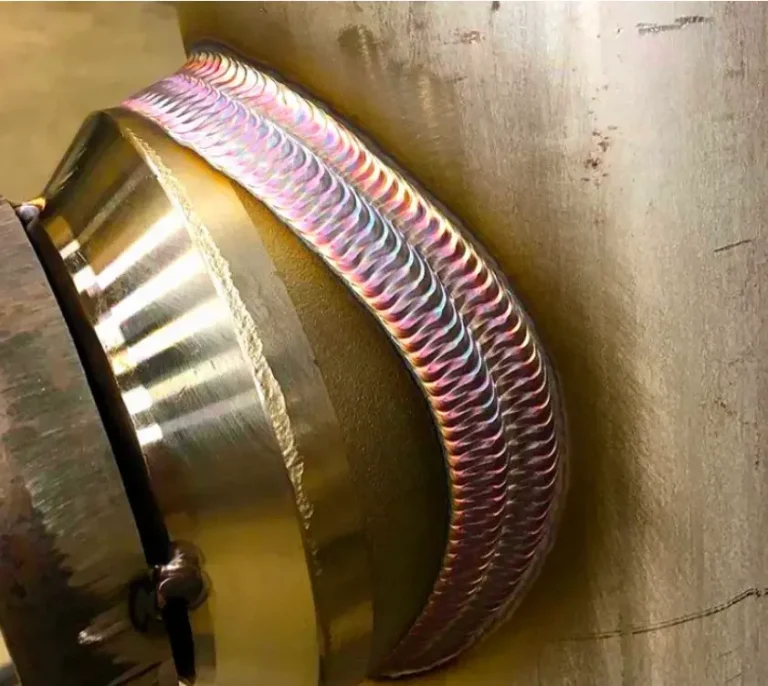

TIG welding steel, stainless steel, titanium and chromoly requires DCEN. Opposite of Electrode Positive stick welding, DCEN is a negative current or Direct Current Electrode Negative. This means that the torch hose is attached to the negative terminal of your machine, and the ground clamp lead is attached to the positive terminal on your machine. This is the most commonly used polarity in TIG welding. DCEN is also called as straight polarity.

In this polarity, most of the heat is directed at the base metal. In comparison, less amount of heat is generated at the electrode. This polarity is thus suited for TIG welding because we don’t want the tungsten electrode to melt.

Dinse Style Connectors are most common in modern day machines and allow for quick changes if needed. Higher end machines such as the Miller Dynasty will allow for polarity changes with the click of a button. This means that you don’t have to physically switch the terminal connections.

Alternating Current TIG (AC)

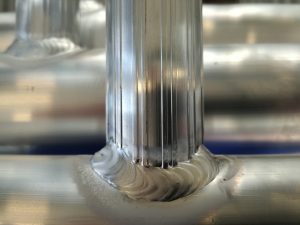

Aluminum TIG welding will require alternating current or AC, in which the machine is constantly reversing between positive and negative currents. The current changes polarity between positive to negative 50 times every second!

Lower end machines usually don’t have this feature. It is essential for TIG welding aluminum, but isn’t as common for hobbyists or general home applications. However, If you plan on TIG welding aluminum, make sure your machine has AC. A good aluminum TIG welding video can be watched here from welding tips and tricks.

Why Is AC Necessary For TIG Welding Aluminum?

The alternating current is almost indispensable for GTAW welding of aluminum. It provides a cleaning action on the surface of aluminum. Such cleaning action does not occur with DCEN polarity. In DCEP polarity, some cleaning action does occur; however DCEP is not a feasible option due to other reasons.

This cleaning action provided by the AC results in the removal of the aluminum oxide film present on the surface of the metal. This ensures that no oxide can enter the weld metal.

The cleaning action can be observed real time by the welder while welding aluminum or its’ alloys with alternating current. A frost like region appears on the metal surface around the arc. As the arc proceeds ahead, so does the frost like region.

Inclusion of aluminum oxide in the weld metal is not desirable. The oxides can render the weld metal hard and brittle.

Side Note

For all things TIG welding, this book helped us out a lot through school and through the earlier parts of our career. Detailed illustrations and in depth chapters help explain just about anything TIG related. We were required to read chapters for our school work, but we kept the book to use as a long term reference.

Electrode Positive TIG? (DC+)

There is rarely a reason to run positive polarity (DCEP) for TIG welding. It will burn up the tungsten and ruin your weld. This happens because in DCEP polarity – most of the heat is concentrated at the electrode. So the tungsten electrode gets heated up and we can see a molten ball at the tip.

In TIG welding, tungsten is a non-consumable electrode. So, melting the tungsten does not fit well in the scheme of things.

Further, the arc is not stable. The operation is not smooth. There is high chance that you would end up with tungsten inclusions in the weld metal. Tungsten inclusion in the weld metal makes it hard and brittle; and therefore susceptible to cracking.

However, you can use positive polarity to your advantage in one key situation. If you need to ball your tungsten for aluminum TIG welding, you can initiate a quick arc on a positive current. Generally just do this for a split second, and then stop. This will form a nice ball at the end of your tungsten. Then, you can switch to AC and begin aluminum welding.

Newer machines will tend to ball the tungsten automatically on AC current, but the positive polarity trick listed above can be useful on older transformer machines. A rounded tungsten performs better on aluminum than a sharpened tungsten.

Switching your Stick Welder to TIG

If you want to run a scratch start TIG setup off your existing stick welder or engine drive, simply switch the DCEP (positive) setup to a DCEN (negative) setup. Switch your leads to opposite terminals – so your stinger lead is now negative and your ground clamp is now positive. Then, clip the stick stinger to your power block adapter for your hoses, and clip your ground to your work piece. You can read more on Scratch Start TIG supplies here.

Some lower end machines will have the TIG leads/hoses hardwired in, with no option for adjustability. This means you can start TIG welding right away. However, if you want to stick weld, you’ll need some machine modifications.

For more TIG welding info, click here.

Below, I have answered a few commonly asked question related to TIG welding polarity. Although most of it has been addressed in the above paragraphs, this is just for a quick reference and recap.

Frequently Asked Questions (FAQs)

What is the most common polarity used in TIG welding?

Direct Current Electrode Negative (DCEN), also sometimes referred to as straight polarity is the most commonly used polarity in TIG welding. For welding of aluminum and its’ alloys, alternating current (AC) is the most appropriate choice.

Why is straight polarity used in TIG welding?

Straight polarity gives the best result while welding with TIG process. In this, most heat is concentrated at the base metal (and not at the electrode), which is what we want.

On the other hand, in reverse polarity (DCEP), most heat is concentrated at the tungsten electrode. This makes the electrode melt, which is something we don’t want.

Is TIG welding electrode positive or negative?

As stated above, DCEN (or electrode negative) is the most commonly used.

Which type of polarity is used in Aluminum welding?

Aluminum can be welded with many welding processes. If TIG welding is used for welding aluminum, alternating current is the best choice because it provides a cleaning action on the metal surface during welding. This cleaning action causes removal of aluminum oxide film from the metal surface. If not removed, the aluminum oxide may enter the weld metal and make it hard and brittle.

What polarity is used for TIG welding stainless steel?

As stated in above paragraphs, DCEN is an apt choice for TIG welding of stainless steel. And not just for stainless steel, DCEN is the appropriate choice to TIG weld carbon steel, chrome-moly steels, titanium, and zirconium as well.

Please do share your thoughts in the comments section below. Thanks for reading.