Is Welding Hard? – The Learning Curve

This post contains affiliate links.

Is Welding Hard?

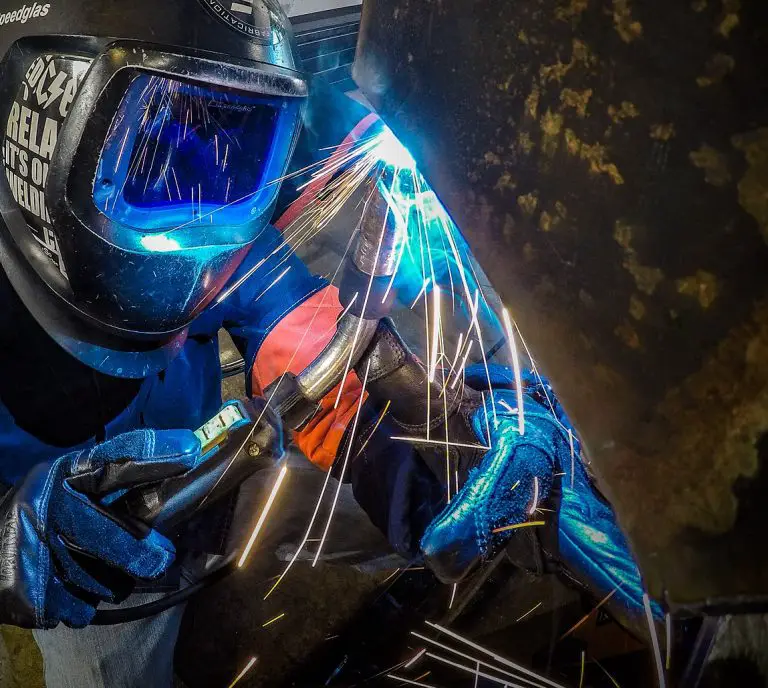

Is welding hard? Well, there’s definitely a steep learning curve. This article will cover the 3 main processes in terms of difficulty and ease of learning. We will go over the types of skills that most people have never had to use in other hobbies. Then we will give our take on the best routes to learn how to weld.

Some new welders have natural talent, while others will have to work harder at it. Just like any skill, it may come easily or you may want to quit right away.

As long as you stick with it, you will see some nice results. The hours you put in will determine how far you take it.

Stick Welding

Stick welding is relatively simple in terms of equipment needed. You have your machine, leads, stinger, ground clamp, and electrodes. Stick welding produces it’s own shielding gas, so theres no need for gas cylinders or refills at the supply store.

With low hydrogen electrodes i.e. 7018 rod, you have to drag the puddle instead of pushing it. Once you strike off, your electrode is angled and you are dragging it away from your molten puddle.

Vertical stick welds tend to require an uphill pushing motion because you are fighting gravity. Uphill stick welding is one of the hardest types to master, especially with a 7018 rod. If you can pass a 3G (vertical test), employers will likely be more interested in your resume.

With pipe welding, a lot of the stick welds are performed downhill. This means that pipeline welders are often running from the top of the pipe to the bottom. There are specialty rods that are meant to be burned this way, but this is not taught very often in welding schools. Although a few key welding schools teach downhill stick, most people learn by becoming a welders helper on the pipeline.

The welders helper position involves prepping pipe and helping the certified welder throughout the day – and then practicing your welds after hours. If you reach a point where you can pass a pipe test, you could secure a job on the pipeline.

Some issues that many novice stick welders face:

– Your electrode is constantly getting shorter as it is burning. You must adjust your hand position as the rod burns down, and many newbies won’t hold the tip close enough for proper electrode penetration. This “Long arcing” can lead to a violent puddle and a very weak weld.

– Arc starts can be very frustrating. Although it is similar to striking a match, many beginners will keep getting the electrode stuck on the steel due to their lack of technique. This proves to be a barrier to entry in terms of completing your first stick weld.

– Travel speed is a tough thing to learn. A lot of new stick welders will pull the puddle too fast or too slow. This results in discontinuity within the bead. You can identify this because the bead will be wider and narrower in different areas. In order to achieve proper bead width, you must maintain the same travel speed throughout the weld. This involves lots of practice and failures along the way.

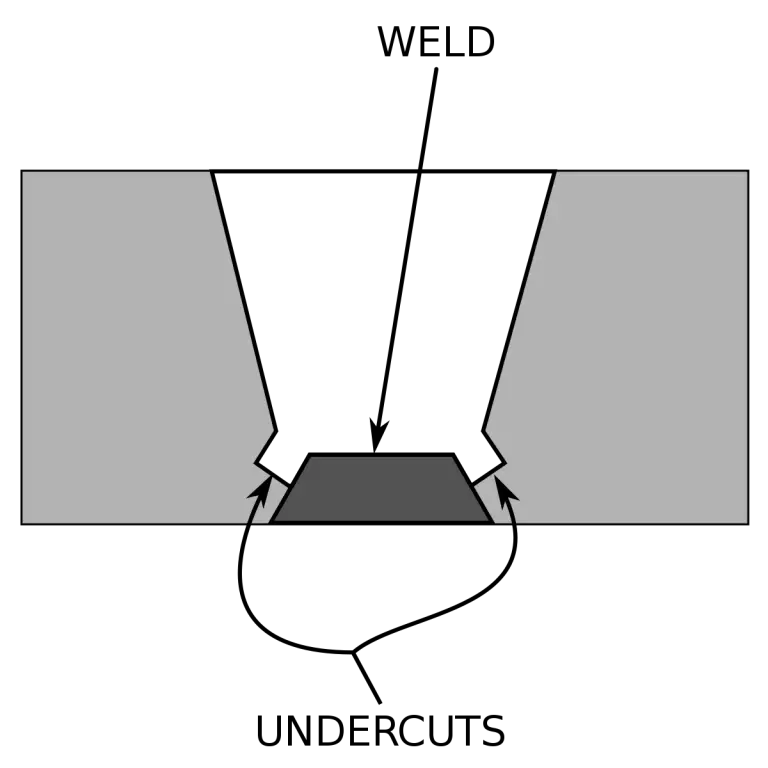

– Cold roll is another issue. If your rod angle or machine amperage is incorrect, you can get a “lack of fusion” along the edges of the weld bead. Instead of being flush with the steel, you will see a sag in the bead, as it has failed to completely fuse with the steel.

MIG Welding

MIG welding is one of the most popular processes. It is the most common method that fabricators use to build different projects – i.e. handrails, gates etc. Think of a MIG gun as a hot glue gun for steel – the wire travels out as it fuses different pieces of metal.

Hardwire MIG is very versatile because users can choose to push or pull their puddle. There is no slag involved because a shielding gas is always used. There are many different movement patterns to achieve multiple types of beads. Whether you want dimes, weaves, or a straight “stringer” bead – these can all be achieved with hardwire MIG.

Flux core MIG can be a little more difficult. It produces a lot of slag and is similar to a stick welding bead. You generally drag the puddle to avoid slag inclusions. These inclusions are when your slag fails to harden on top, and it will mix the weld. These are considered defects, and many beginners will have these defects in their weld.

Stainless MIG tends to run a bit more sluggish, and beginners will find that it is hard to manipulate their puddle. Stainless wire is also a lot more expensive, so it is pricey to learn this specific process.

Some issues that novice MIG welders face:

– The machine is more complicated to set up than a stick machine. You have to deal with wire speed (inches per minute), gas flow (cubic feet per hour), voltage, and drive roll tension (pressure on the wire). Once you have your machine set right, MIG welding can be a breeze, but you must thoroughly read your manual, or else you will be presented with subpar weld beads. Beginners may find it frustrating to set up their machine. It is also hard for beginners to memorize the right settings for different projects.

– Lack of fusion is also an issue with hardwire MIG. The welds tend to be more brittle than a stick weld, and lower amperages can lead to very weak beads. We recommend that beginners always remove their mill scale with a grinder to achieve better weld penetration. Lack of fusion can lead to welds cracking – this can be a safety hazard (especially on larger projects).

– Necessary MIG equipment such as contact tips and nozzles can be confusing for beginners. These vary based on wire size, and can take some practice to memorize.

TIG Welding

In our opinion, TIG welding is the hardest process for beginners to learn. It involves great dexterity and very steady hand movements. Generally, your dominant hand holds the torch, which must be moved very steadily to push your puddle. This is because the tungsten electrode will get contaminated if it taps the base metal or the filler metal. We’re not saying you need to have the hands of a surgeon, but you should try to be in that ball park.

Also, feeding rod with your non dominant hand requires lots of practice, trial and errors. There are multiple ways of feeding filler rod (i.e. traditional grip, kane grip etc.) that users must play around with to get situated. These filler movements can be practiced at home during your free time.

Some issues that novice TIG welders face:

– Foot pedal control can be tough. You already have both of your hands filled – one holding the torch and one holding the filler rod. On top of these tasks, the foot pedal must be adjusted properly throughout your weld bead. This amperage control can be very frustrating for beginners. It can be especially annoying for beginners that don’t have decent coordination to begin with.

– Tungsten contamination happens very often for novices. When the tungsten touches your steel or filler rod, the steel will fuse to it and ball up. The tungsten will no longer hold a solid arc; and it must be re-sharpened to get back to welding. Constant trips back to the bench grinder to sharpen tungsten can make beginners feel like they aren’t making progress.

– New TIG welders also face inconsistency in their welds. They made lay a good bead here and there, but they will probably struggle with the process for awhile. This is very normal. Until your technique becomes proficient, your beads will reflect the fact that you are still a beginner.

– Welding vertical and overhead with TIG adds additional difficulty due to arm positioning, and novices will get frustrated by the awkward hand movements that these positions require. This will lead to more tungsten contamination and weld defects.

Advice For Beginners

There are many routes you can take when learning to weld with these different processes. Youtube has tons of instructional videos with channels like weldingtipsandtricks, 5th street fab, weld tube, etc.

Personally, I went to a well regarded welding school in Colorado. All in all, it was a decent experience; but I felt a lot of it could have been learned online. The benefit of welding schools is that they usually offer AWS certifications at the end of your courses. Passing these bend tests opens up a new world of job opportunities which can be very rewarding.

You may also know a welder through family or mutual friends that could help get you started. I have taught some basic lessons to my buddies and they ended up with some nice looking beads. There are also many smaller trade schools and studios that offer shorter courses for beginners. If you don’t want to dive head first into welding, you can take some night time classes to get a feel for it.

Our best advice is that if you are looking at welding for a career, then it is best to pick a reputable school. Putting 2 years into it will leave you quite skilled. If you just want to pick it up as a hobby, then a shorter course or some online videos can be very beneficial.