How Long Should My Stick Welding Leads Be?

This post contains affiliate links.

When it comes to stick welding (arc welding), there are many different possible applications for this process.

You may be welding off a Lincoln buzz box in your garage, or you may be using an engine driven machine to perform large structural welds.

Lincoln Tombstone AC Welder – Check Price On Amazon

Your ground lead and your stinger lead must be long enough to reach your project. If they are too short, you won’t be able to weld at all. This can be very frustrating and can even cause you to lose a job that you would have made money on.

When welding in a garage or a home setup, you may only need 10-20 feet of length for each lead. You may be able to set the welder right near your fab table and get to work. This means that you will spend less money on the leads than a rig welder would.

Recently when I purchased the new Miller Bobcat 225, I knew that I needed a long set of leads to go with it. I do mobile welding and I must be able to reach projects that are far away from my trailer.

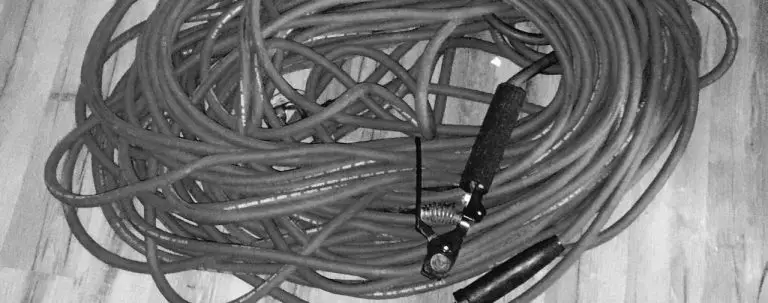

I went with 1/0 leads – these are very heavy duty and can burn just about any size of electrode. Coming in at $2.22 a foot, the cost adds up quickly. 125 feet of ground and 125 feet of stinger lead ran me $640. Paired with a Stinger V, ground clamp and Tweco connectors, I spent around $800. Although this is costly, it will allow me to reach just about any project I get hired to weld on.

Pipeline welders will usually run about 100 feet of leads (both ground and stinger). For those not familiar, the stinger lead is what holds your electrode to complete the weld. The ground lead allows that electricity to flow back into the welding machine while you’re welding. It is basically one big loop of electrical current.

Welding Lead Set – Check Price On Amazon

Generally, field welders (mobile welders) will need more length to reach different projects. Shop welders and fabrication welders can get away with a shorter set. Usually they are working at a fabrication table and their machine is right next to them. This is why MIG welders often come with a short set of leads (MIG is more common for fabrication).

Farm workers and ranch workers can get away with a medium set of leads. 50 feet or so will allow them to tackle fence projects, gates and more. I used to do a lot of farm work and a 50-60 foot set allowed me to tackle most projects with ease.

The problem with really long leads (150’ or more) is what is called voltage drop. This means that when using super long lengths, there is a drop in electricity before it reaches your electrode. This can cause issues because you are not getting the proper amperage sent to your stick electrode. Welders will generally avoid these long lead lengths for this reason. If you are going to run a setup that is 150’ or more, you’ll definitely want to get a larger diameter lead. 1/0 and 2/0 are most common for this. They can handle higher amperages at longer distances.

It all comes down to personal preference and what you plan on welding. You can always splice leads and add more, but it is better to get the right length in the first place. Although they are expensive, it is worth the investment because they last awhile and are very durable.

You can always start off small and then upgrade as you start to tackle larger projects.

Thanks for reading.