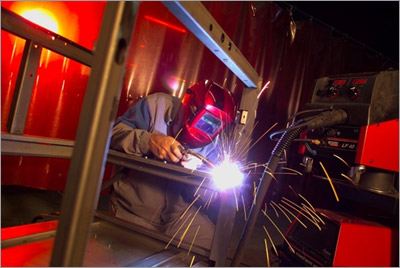

Welding Blankets – What Are They?

This post contains affiliate links.

Welding blankets have been used for a long time for their protective properties. But what exactly are they?

Welding blankets are large flame resistant cloths that cover areas that should not be burned. These areas may include finished interiors, valuables, or vehicles. Basically anything that should not get sparks on it.

As welders, we often have to weld in some pretty undesirable places. While we prefer welding in a shop or a garage setting, sometimes we must weld where there are nice interiors or finished items nearby.

A good example is installing a hand rail inside of a finished house. Obviously, nothing in the house should get sparks on it – but we must weld anyways to complete the job – this is where the welding blanket comes in to play.

How To Use The Welding Blanket

Depending on the area you must cover, you may need a large blanket or even multiple blankets. Taking proper precautions will ensure that you don’t damage any valuables.

Place it in the immediate area where you think the sparks will fly. Obviously with Stick and MIG welding, sparks are going to travel quite far. With TIG welding, you’re really just concerned with the occasional sparks that may damage something.

This should be obvious, but the best welding blanket is a new one. Old, worn out blankets aren’t very helpful since they may have holes in them. This will make it far more likely that you will get sparks in the wrong area. Always be wary of using someone else’s blanket, and be sure to inspect it prior to welding.

These blankets can get pricey, and we understand that not every welder can afford to buy multiple ones. If you’re going with just one blanket, simply place it in the immediate area surrounding your welding joint.

For extra precaution, you can extend the area by overlapping multiple blankets. Make sure that there are no exposed areas where the blankets meet. It is impossible to un-burn an area once you get sparks on it.

Are There Alternatives?

Simply put, there is no great alternative. but there are some options that can get you by.

Wetted cardboard can work in a pinch if you really need it. Simply spray down some large, flattened cardboard and use it as a makeshift blanket. Dry cardboard presents a fire hazard in itself, so we really don’t advise it.

The problem with using wetted cardboard is that it gets soggy pretty fast. If you are working on a larger project, the cardboard will probably deteriorate before you are finished welding. This can be a serious mess to clean up, so we really don’t recommend it unless you have to.

Keep in mind that on actual job sites, supervisors will probably not allow anything besides a welding blanket. There’s a reason why they work so well, and using anything else can be viewed as a hazard (especially by insurance companies). However, if you are doing your own personal projects, then feel free to experiment with alternatives (at your own risk).

Less porous materials like Ram board can work quite well. They don’t ignite very easily and can be spread over a larger area. However, a roll of Ram board can be pretty costly, so you might be better off just getting a blanket to begin with.

Other protective coverings are generally disposable. When you consider that the welding blanket is reusable, it really makes it look like a bargain. We have had some of our blankets for years and they are still holding up – whereas Ram board or cardboard must be thrown out after your job is finished. It is hard to transport, whereas the welding blanket can just be folded up and thrown in the truck.

What Are Welding Blankets Made Of?

The makeup varies depending on the model – but generally, these blankets are made of fiberglass strands that are woven together. These are heat treated to ensure that they have maximum flame resistance.

Other materials that may be used include vermiculite and different non flammable compounds. However, we recommend the fiberglass blankets because they are very durable and quite supple.

As with any welding item, it will wear out eventually. Keep an eye on your blanket for holes or frays. Once these blankets start to rip, they can go downhill pretty fast. This is especially true if you are using a heavy duty process like Stick welding. The more sparks that are flying, the more abuse your blanket will take. The same rule applies for welding jackets, pants and gloves – you get the idea.

Best Models

Below we have listed some of our favorite welding blankets. Factors such as durability and price point definitely are a factor. We have used these blankets and are confident that they will hold up during your next welding project.

Keep in mind that the lighter color blankets will look pretty trashed after awhile. Not that it matters too much, but darker blankets still look decent after many usages.

Make sure to research and get the right sized blanket for your job. Getting a tiny blanket in the mail can be pretty disheartening if you are doing a large project. Happy welding!

OASD 6×6 Welding Blanket – Check Price On Amazon

High cost, but the durability is great. If you’re looking for a long lasting option, this blanket is worth looking at. It really does well at repelling heavy duty sparks, and withstands repeated abuse.

ABN 4×6 Welding Blanket – Check Price On Amazon

A good smaller, less pricey option. This blanket is good for hobby projects in the garage or welding around the farm. It is a great starter option for welders on a budget. However, it gets dirty fast!

Featured image credit : Pixabay.com