How To Deal With Welding Customers

This post contains affiliate links.

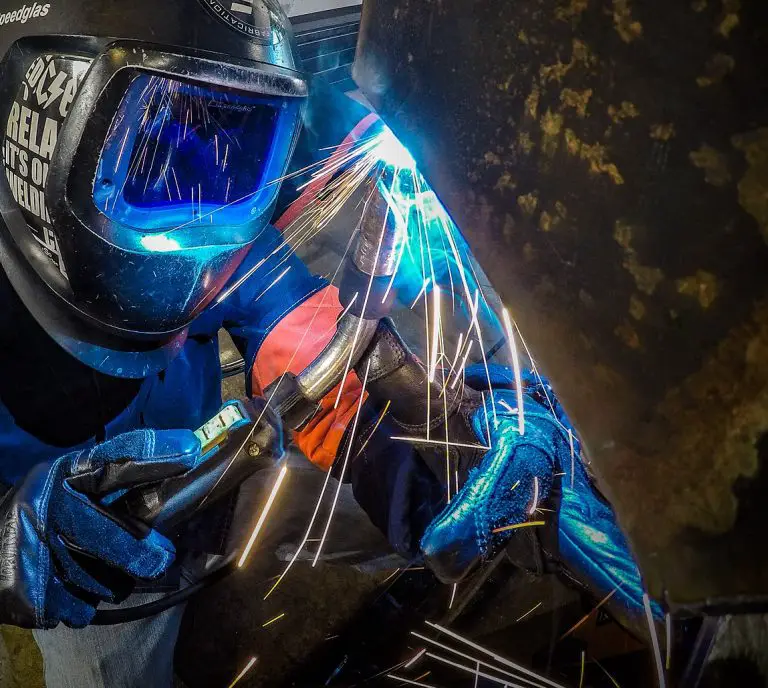

If you run your own welding business, you know that customers can be a hassle to deal with sometimes. Even though they are the ones keeping you running, there are some helpful tips that can help you deal with them easily.

This article will go over the most common problems that we face with our welding customers. How you deal with this can make or break your business, but it really just comes down to common sense and being a people person.

Wanting Something Welded For Cheap

So you’ve invested all of this money to buy your welder, tools, truck and equipment. Now you’re getting a call to weld a muffler on for $50. Ugh!

This brings up the importance of having a minimum. For our mobile services, we charge a $200 minimum. This covers the first 2 hours or less. Therefore, if we spend 30 minutes welding a muffler on, it is still a $200 job. This helps to keep you profitable while remaining honest. When clients know your minimum charge, they will understand that even a small job will cost them 2 bills.

Obviously, the exact rate will be based on your specific area. Here in the Aspen valley (CO), $100 an hour is pretty standard. Your state may be less (or more!).

We also see clients that say “it will only take you 20 minutes!”. Wrong! We, the welders, know how long it is going to take. Someone who has never welded before has no business telling you how long a job will take. Once again, the importance of a minimum charge comes into place. Whether it takes 20 minutes or 2 hours, the price remains the same.

For our mobile services, remaining hours (3rd, 4th, 5th, etc.) are $85 a piece. Our minimum is basically $100 an hour, but the $30 buffer helps with gas and consumables. For those unfamiliar with consumables – these are stick electrodes, grinding wheels, blades etc.

It also means that a client that books us for a longer job will get a discounted rate. After the first 2 hours that are $100 each, they will start to pay less. This means that clients with larger jobs can take advantage of the remaining hours at a lower price. It’s a win win for both parties.

With this being said, mobile jobs are generally more expensive than shop jobs. When you fabricate something in a shop, it is usually a fixed bid. You take your time building the piece and then the customer pays the price that was agreed upon.

Mobile jobs are usually more urgent. Emergency cracks and breaks means that the client is willing to pay more to get back to business. Service calls must be prompt, and clients understand that the rates will be higher.

I Just Want It Welded, Don’t Care How It Looks

Some customers will say this to you. They want it welded as fast as possible and they don’t care how the bead actually looks.

This is problematic for a welder. First of all, we don’t want our welds to look bad. We want every bead to be pleasing to the eye. We want customers to show our welds to other potential clients. If we lay a bad bead and our name is behind that weld, then getting more jobs is much less likely.

It is important to educate clients that the welds must be done right. This is better for the customer and it is better for future business. If the welder takes their time prepping and does it right, then this prevents chances of cracks and breaks in the future.

Even if you are doing a small job that only requires a few welds, making those look awesome is the right way to go. This is true for any trade, the tradesmen wants to do it right and wants to stand behind their product.

Clients that understand this mindset are the best ones to have. They let you do your work and they trust that it will be done right. Hopefully they have already seen photos of your work – This helps build trust.

Price Shopping

It is important to stand behind your business model. Don’t waiver under any circumstances. If a potential client says that they found someone who will do it cheaper, then you must be ok with them hiring that person. When that weld breaks, they will definitely be calling you.

This goes for other professions as well. I have two half sleeves done mostly by a veteran tattoo artist. When I got tattooed by an apprentice, the price was good, but the quality was poor. I didn’t like making a dent in my wallet by hiring the good artist, but the tattoos were 10x better.

Any customer that wants to price shop is totally allowed to do so. They are usually a hassle to deal with, and it’s probably better that you don’t even work for them in the first place. They will nickel and dime you, and they are usually the ones standing over your shoulder while you’re trying to work.

Nagging Customers

These are the customers that can’t just sit back and let you do your job. They will fuss over every little thing. Instead of leaving you to your duties, they will watch you like a hawk. This is a terrible thing because it makes it hard to focus on what you’re doing.

When customers do this, I usually won’t work for them again. I’ll complete the job and do it right – but if they call back, I won’t be accepting any more jobs from them.

Wrap Up

All in all, running a welding business just takes common sense. Knowing how to deal with people will have a positive effect on your business.

It will also help you to know which customers present red flags. Turning down a job is totally ok if you’re getting bad vibes.

The best clients are the easy ones, and that’s the way it’s always been.

Thanks for reading.

Featured image credit : Pikrepo.com